Have you ever wondered how those hard-shelled mollusks known as mussels anchor themselves to rocks on lake and river bottoms? How they stick to sea walls, or resist pounding waves?

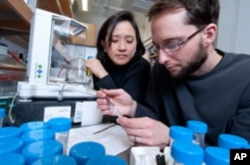

Scientists at the University of Chicago have done more than come up with some answers. They’ve actually created a synthetic gel that mimics the mussel’s sticky, self-healing properties. Their invention could have far-reaching medical and industrial applications.

Niels Holten-Anderson - a post-doctoral scholar at the University of Chicago - says mussels do two things really well. They excrete a sticky adhesive and they can use that natural glue to repair the anchoring bond.

"And the important thing to remember is that there are no cells. There is no live or living activity taking place inside these materials. The material is basically a dead material, just like our hair," says Holten-Anderson. "So this capacity to re-heal itself is completely automatic, and it’s not relying on any energy input from living cells."

Holten-Anderson, his University of Chicago colleagues and a team of international scientists worked on how to turn what mussels create naturally into a synthetic material. They zeroed in on the chemistry of what the mollusks secrete and discovered metal mixed inside their thin, hold-fast fibers. Holten-Anderson says iron is a key ingredient that makes the adhesive strong and flexible.

"The unique thing is that you can pull them apart and if you leave them be, they can find their partners again and re-heal, and that’s where the original strength of the healing comes from."

Holten-Anderson and colleagues set out to replicate that in the laboratory using a synthetic polymer or a simplified version of a string of mussel protein molecules. They succeeded when they pre-mixed the polymer with metal salts at low pH.

"You instantly get an initiation of these self-healing gel-like, sticky materials as soon as you do this basically step-wise process of mixing things," he says, "and then increase the pH potentially mimicking what happens in the natural case anyway."

Iron is the metal available to mussels in the environment. Holten-Anderson says scientists can expand that pallet and experiment with other metals.

"We’ve shown so far that a metal such as titanium, for example, which is interesting from the bio-medical side of things with implants materials and so forth, that we can actually use titanium atoms too to cross in these materials and those materials seem to have even stronger, even higher strength than the iron based materials."

Holten-Anderson expects the nature-inspired material will have practical medical and industrial uses. A patent is pending on how to make the gel, which is described online in the Proceedings of the National Academy of Sciences.