Vertical farming — a tech-savvy subset of farming in which plants are stacked indoors, floor-to-ceiling, using controlled-environment agriculture (CEA) methods — is growing rapidly, changing the business landscape of traditional supply chains and growing seasons.

It is also having a profound effect on the environment.

Ask Newark, New Jersey-based AeroFarms, which set up shop in a neon-sprayed former paintball and laser tag arena next to a highway in the city’s Ironbound district. Its warehouse is the size of a Walmart Supercenter, but exclusively for leafy greens and herbs — more than 250 varieties.

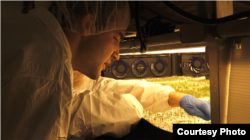

AeroFarms aisles rise tall — accessible only by forklift crane — with shelves that are specialized growing labs using patented LED lights, aeroponic mist and reusable cloth.

To enter, farmers must suit up appropriately: gloves, lab coat, hairnet. Shoes must be disinfected.

AeroFarms’ high-yielding, economically efficient technology has made it the commercial leader in indoor farming, a market that is expected to quadruple over the next five years to nearly $4 billion.

AeroFarms co-founder and CEO David Rosenberg says the decision to focus on leafy greens was not based on any technological constraint, but rather business optimization.

“These are relatively high price-per-pound items, so it absorbs some of the price premiums with the new technology,” Rosenberg said.

95% water reduction, zero pesticides

AeroFarms’ output is consistent year-round, and it's consistently good for the environment — the effects of soil erosion, pesticides, water overuse and carbon emissions are heavily reduced, in some cases eliminated. The result is a net win for AeroFarms and the Earth.

“We could take up seed, we could grow it using 95 percent less water. In about 16 days our output per square foot is approximately 80 times per square foot over a field farmer, and we also grow using about 50 percent less fertilizers and zero pesticides, herbicides, fungicides,” Rosenberg said. “We could do this whether it is in the Sahara or a city like Newark.”

With indoor farms already in development on four continents, AeroFarms co-founder and chief marketing officer Marc Oshima says the company’s goals are to increase its production efficiency and scale operations worldwide near major distribution channels.

“We look at every single major urban environment as an opportunity,” Oshima said. “We look at things like urban density, we think about population, we think about people who are eating leafy greens.”

They also consider plants that are specific to their audience.

“We think about amaranth, one of the most popular greens in Africa and Southeast Asia. We think about how we can really bring and celebrate different types of varieties and different types of greens that are going to be specific to those regions.”

Baby watercress, specialty kale

The farms also serve as tasting labs for AeroFarms' packaged varieties of supermarket-available, ready-to-eat leafy greens. Its baby watercress — labeled as “bright and crisp with a slight sweetness and a healthy dose of spice" — also happens to be an AeroFarms office favorite.

Alina Zolotareva, registered dietitian nutritionist and self-described foodie at AeroFarms, says her objective, from a public health standpoint, is to get people to eat more leafy greens like kale, one of the most nutritionally dense foods on the planet. To achieve this, producing the perfect taste is essential.

“Americans especially don't eat enough vegetables, so for me the most exciting part is all of the different flavors that we have here,” Zolotareva said. “It makes eating your vegetables so much more exciting and so much more fun.”

The farm’s specialty kale, in her opinion, “melts in your mouth.”

“A lot of people like the nutritional density of kale, but they don’t like the taste,” added Rosenberg. “So we can make a sweeter kale using the same seed, just stressing a plant to change the phytochemistry to get certain outcomes.”

6,500 square meters = 900,000-kilo harvest

Rosenberg says AeroFarms’ focus on leafy greens serves a greater function in addressing a growing food shortage worldwide. As part of a multifaceted approach to the crisis, he says consumers must shift their focus from calorie intake to nutrition.

Recent studies by the World Bank predict that an estimated global population of 9 billion in 2050 will require at least 50 percent more food. To add to the crisis, climate change is projected to cut crop yields by more than 25 percent during that span, an effect that would disproportionately affect the world’s poorest citizens.

AeroFarms, for its part, is slated to increase production significantly in the United States, in addition to its global operations. Less than a kilometer from its 2,800-square-meter farm is the site of its new global headquarters, a 6,500-square-meter former steel mill — the largest indoor vertical farm worldwide based on annual growing capacity, with a harvest rate of up to 900,000 kilos.